“Ouroboros” by Daniel Wayne Miller

Title:

- Ouroboros

Artist(s) and People Involved:

Exhibiting Artist(s):

Symposium:

- ISEA2016: 22nd International Symposium on Electronic Art

-

More artworks from ISEA2016:

Venue(s):

Creation Year:

- 2016

Medium:

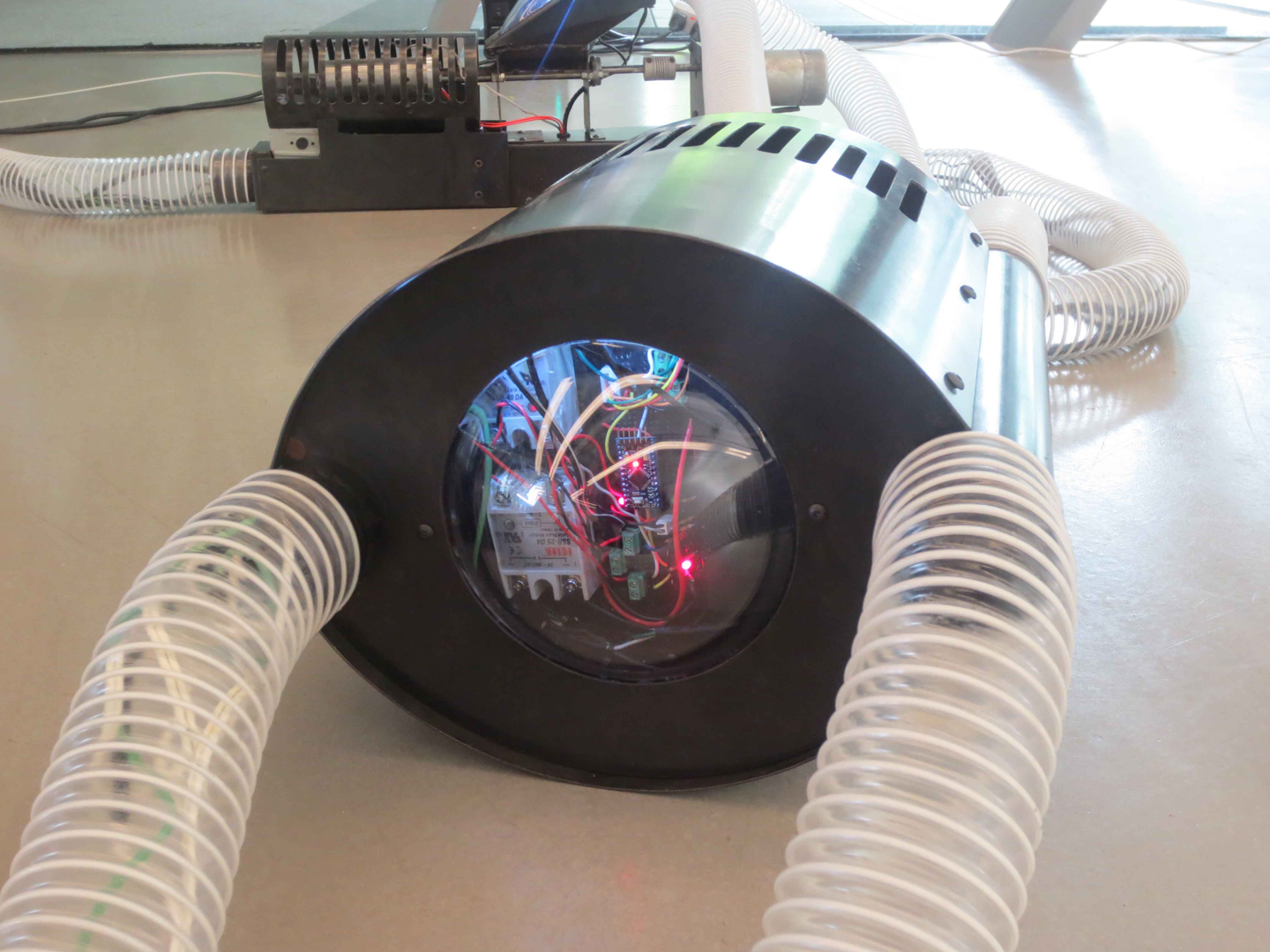

- Steel, aluminum, poly carbonate, HDPE, vacuum hose, vacuum, wire, dc motors, LED’s, fans, heater, heat controllers, microcontrollers and various electronics

Artist Statement:

The Ouroboros is an ancient symbol of a serpent or dragon eating its own tail. Here something is constantly recreating itself. This symbol has a variety of interpretations and is found represented in number of ancient cultures, the two oldest being China and Egypt. One interpretation of the Ouroboros is the idea of the eternal return, where the universe is has been recurring forever.

Ouroboros the robotic artwork is an embodiment of this idea. Using various DIY mechanisms and components this robot extrudes a plastic coil like “tail” that winds across the floor. The “tail” ultimately is returned to the robots “mouth” as a vacuum and rollers in the machine intake the plastic “tail” grind it back up, melt it down and re-extrude the tail as a new coil. The interaction of material, process, variation and machine connects to many other possible interpretations including ideas from: biology, ecology, behavior studies, industrial production and micro-manufacturing.

HDPE, High Density Polyethylene is the common material used in everything from milk jugs to toys and cutting boards. With proper collection and resources this material is easily recycled. Instead of using a ready made filament or plastic pellet the Ouroboros robot only consumes shredded plastic milk jugs. It will thus only recycle and renew as long as it has its tail or extra shredded recycled plastic to consume. Obvious parallels are made here between the symbol of the Ouroboros and the potential of a recycling system.

The tail of this robotic serpent will have the capacity to enlarge as it recycles with each generation from vacuuming in additional the plastic source material covering the floor. In addition to the “tail” enlarging there will be variation in each new iteration of the tail. A form of reincarnation occurs through constant rebirth of the Ouroboros’s plastic tail. This “Tail” material is melted at a safe temperature of 350 degrees Fahrenheit or less where minimal off gassing will occur. All heat and shredding components are safely secured inside the “body” of the Ouroboros mechanism. Blow formed transparent polycarbonate panels will provide windows into the body of the serpent robot where observers can witness these processes unfolding. Select parts of the robot are also made from recycled cast HDPE using a different process than the extruded tail. These recycled mechanical parts will be cast and fabricated in Daniel Miller’s studio at the University of Iowa.

The processes used in Ouroboros connect to a larger DIY community where recycling of plastics into 3D printing filaments and other components provides a possible real low cost alternative for individuals and production at the local level worldwide. The DIY systems used within the Ouroboros represent a shift in hierarchy from governments and corporations to open source communities and individuals. This shift has been taking place for the past 20 years, as robotic technologies become ever more accessible at the local level. DIY systems used in the Ouroboros include: Ardunio controllers, homemade filament extruders, a repurposed vacuum cleaner and various prototype mechanisms. While some of the Ouroboros’s structural components are made with CNC tools other parts like the polycarbonate windows are made with simple electric cooking ovens and compressed air. The Ouroboros challenges ideas behind automation and manufacturing. Robotics has infiltrated ever level of manufacturing. Commercial production processes have been key to the ever-evolving bio-political relationship between humans and their natural world. The Ouroboros approaches these ideas from a more intimate and social level where the micro-manufacturer can change relationship between machine and body.

One can regard the human animal as not above, separate or other but rather equal to the world we inhabit. The effects of human technology are woven into the destinies of all beings of this planet. While the Ouroboros directly references the serpent or snake form, its mythology is also very much human. I am interested in the internal function and flow that occurs within the body. The recycling system that takes place within the body of the Ouroboros both looks at ideas of mechanical manufacturing and material processing and the biological analogues to these processes. Further correlations can also be drawn between this project and the natural recycling system of plant earth as shown through plate tectonics.

Technical Information:

This work is can be installed on the floor or on a low platform. It is intend for the visitors to walk around the work and have access to view the inner works of the mechanism through the polycarbonate windows in the elements. If possible, it would be nice to allow the extruded plastic tail to hang down or trail over a stairwell, staircase or elevated floor. The dimensions of the project can vary with the space due the expandable hoses that connect the mechanical systems.

Floor Space Dimensions: 12ft x 12ft (3.65m x 3.65m) is preferred, with a minimum of 8ft x 8ft (2.43m x 2.43m) required.

Preferred Lighting: Spot lighting is desired for this work, general floodlights would be sufficient. When the project is complete it will have internal light sources in various components.

Power Requirements: This project will need one 100-240 VAC outlet with 10 amps available. A floor outlet is preferred but a wall outlet would be sufficient.

Sponsors:

This project is funded with support from an Old Gold Summer Fellowship from the College of Liberal Arts and Sciences and The School of Art and Art History at the University of Iowa.

Video:

-

Ouroboros by Daniel Miller from Daniel on Vimeo.

Ouroboros–work in progress documentation from Daniel on Vimeo.

Category:

All Works by the Artist(s) in This Archive:

- Daniel Wayne Miller

Ouroboros

[ ISEA2016]

Light Structures

[ ISEA97]

Gradual Slip

[ ISEA2017]

Chiroptera_Domus

[ ISEA2012]